After the 2016 Dayton Mini Maker Faire, the Make It Dayton team took a long, deserved break – mostly so we could spend a little time getting back to our own maker projects! We had a fantastic first year for our Maker Faire on July 16, with over 2500 attendees and more than 50 exhibits and hands-on activities scattered across Carillon Historical Park. Now that we’re all rested and refreshed, we’re gearing up for the 2017 Dayton Mini Maker Faire.

This year, the Dayton Mini Maker Faire is expanding to a 2 day event, August 5-6 2017. We’ll be launching our Call for Makers this January, so keep an eye out for our newly revised and simplified application form. This year we are focusing on adding classes, speakers and more hands-on workshops to the event. We are working on bringing in a 2-day HAM radio certification course, and a very big name speaker and author who has been featured in Make: Magazine.

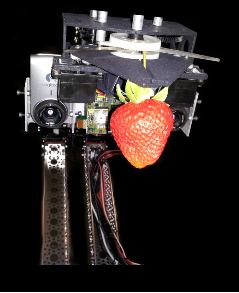

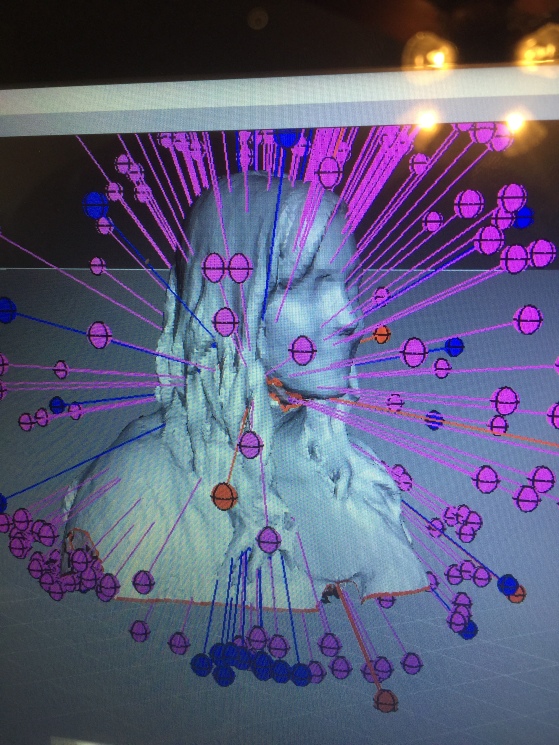

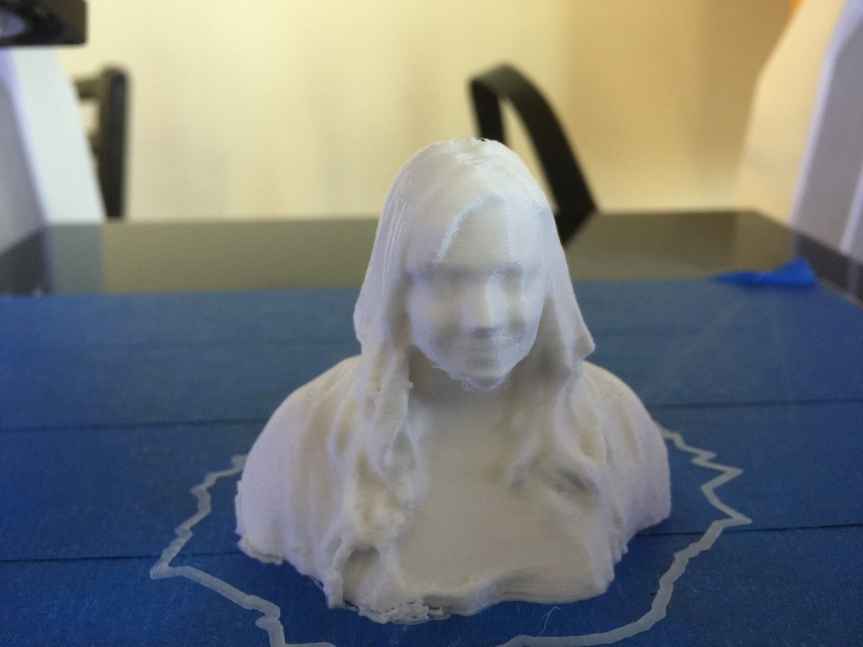

You can learn more about all our new ideas for the 2017 Dayton Mini Maker Faire this weekend, November 5-6 from 12-5pm, at the Dayton Mall Barnes & Noble Mini Maker Faire. We’ll be one of the featured exhibits along with Dayton Diode, STEAMWorks Labs, Proto Buildbar and Boro Moms & Beyond. Get an up-close look at the winning go-cart from the Boneyard Build-Off, check out some cool EL wire, HAM radio and electronics projects, and see some 3D printed stuff at our table. We are excited to be partnering with Barnes & Noble for 2017, and look for their pop-up shop at Carillon Park during the Dayton Mini Maker Faire August 5-6.

If you can’t make it to the Barnes & Noble event this weekend, mark your calendars because Make It Dayton will also be at the Science Festival during Super Science Saturday at the Boonshoft Museum, November 19 from 10am-4pm.

Finally, if you’re looking for a way to get involved with Make It Dayton, or want to volunteer at the Dayton Mini Maker Faire this summer, be sure to follow @makeitdayton on Facebook and Twitter, and join our Meetup group at www.meetup.com/Make-It-Dayton/. We have been holding casual meetups at local coffee shops called Maker Mornings. We have them every few weeks on Saturday mornings, and we try to rotate locations around town. You can also reach us at makeitdayton@gmail.com. We are looking for people interested in being part of the planning committee, but also for our street team that hangs flyers around town and for our day-of Maker Faire set-up, tear-down and event teams. These are all great opportunities for high school or college students, boy and girl scouts, or other youth groups looking to record some volunteer hours supporting Dayton History, the non-profit that runs Carillon Historical Park.

We hope you’re getting excited about next summer’s Dayton Mini Maker Faire! We can’t wait! For all the latest news and announcements, be sure to subscribe to this blog as well as follow @makeitdayton and @makerfaireDAY on Facebook and Twitter.